Submerged Aerated Fixed Film (SAFF)

Submerged Aerated Fixed Film (SAFF) technology is a process used to reduce the organic loading of residential and commercial sewage / waste water, and in doing so will reduce the Biological Oxygen Demand (BOD) and a significant quantity of Suspended Solids (SS) which if otherwise untreated would contaminate river and sea ouValls, in other words it is used to substantially improve effluent discharge quality.

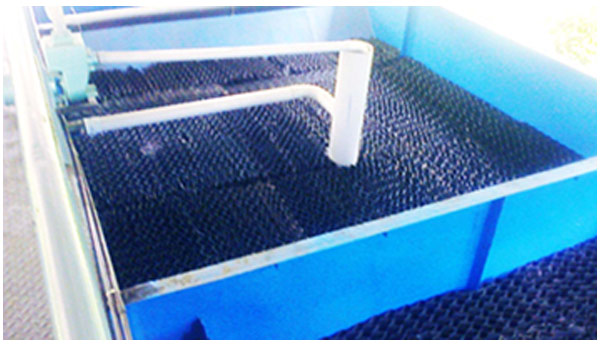

In the wastewater industry, SAFF Technology is used commonly for commercial and residential sewage sanitation / waste water treatment, particularly for small to medium range flow requirements. The air for process is supplied through mechanical aeration system arrangement which consist of blower and diffusers. The structured SAFF media arranged in reactor is fixed with bottom support arrangement.

As with traditional sewage treatment, Submerged Aerated Fixed Films technology uses three stages of dealing with commercial and residential sewage / waste water.

Primary Settlement

- Where larger solids settle into the bottom of the primary tank and are removed periodically as sludge, and where other buoyant materials float upwards to be removed usually by a scraping/screening method.

Secondary Treatment

- Where larger solids settle into the bottom of the primary tank and are removed periodically as sludge, and where other buoyant materials float upwards to be removed usually by a scraping/screening method.

Final Settlement / Clarification

- Where remaining solids (Humus) are settled out of the biological treated effluent.

Discharge Quality

- The usual design criteria is to produce an effluent quality typically better than BOD 30 mg/l & SS better than 100 mg/l. Without additional nitrification and treating, normal domestic sewage ammonia discharges are around 10 mg/l.